Spain – Ver la versión original en español: In 2005, in Spain a specific standard and a new Motorcyclist Protection System (SPM), was developed to improve the safety of motorcyclists in case of a fall and impact against a metallic crash barrier.

Spain – Ver la versión original en español: In 2005, in Spain a specific standard and a new Motorcyclist Protection System (SPM), was developed to improve the safety of motorcyclists in case of a fall and impact against a metallic crash barrier.

It was after the protests of bikers in 2001 and 2002 when the Minister met representatives of riders and promised to work for a solution.

This resulted in the UNE135900 standard and conforming to this standard the first SPM of Spain was developed by the Ministerio de Fomento (Ministry of Public Works). This was December, 2004.

The process and the work for the creation of the UNE135900* standard was completed within a committee that promoted the Ministry of Public Works, which was led by Andrés Perez Rubio, amongst others.

Though metallic crash barriers are the system most used in the design and protection of the roadside, this system was a source of danger for bikers and a challenge for the administrations given the amount of finance necessary to implement the new SPM.

The awareness of this danger was such that the administrations were initiating their own solutions to lessen the danger to bikers without establishing the effectiveness of the solutions.

|

|

The complexity of the road network and the diversity of road administrations with overlapping responsibilities, meant that there did not exist any legal obligation to implement the most suitable elements of safety, because there were their own managers of the road and could determine what measures to install for the safety of bikers.

The complexity of the road network and the diversity of road administrations with overlapping responsibilities, meant that there did not exist any legal obligation to implement the most suitable elements of safety, because there were their own managers of the road and could determine what measures to install for the safety of bikers.

The most common case, continues to be due to costs, to protect the metallic barriers with existing solutions, so that any advance continue to be slow.

Nevertheless, some administrations agreed to install these new safety elements and took into consideration the criteria of the design of the route such as the radius of the curve and more difficult issues such as concentrating on the specific points by focusing on the accidents of the riders (TCA).

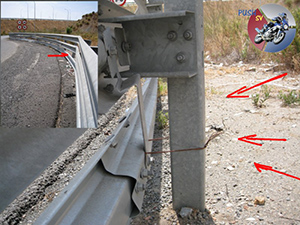

At the beginning, faults proliferated with the new SPM elements when they were assembled, this was probably due to the engineers not understanding how the barriers should be put together while fitting them.

This situation has now been overcome because of the availability of new information and experience that the companies now have.

|

|

|

|

Gradually, Spanish roads have begun to be safer, undoubtedly stimulated by the research and development of the Ministry of Public Works, as well as the installation of SPM and the substitution of dangerous metallic crash barriers.

To a lesser degree, other administrations have made a commitment for the safety of some of the principal cities and are managing to promote the need for safer roads for all road users including bikers.

The challenge continues for improved regulations and the obligation to evaluate the safety of the road infrastructure before it is designed which is a priority in order to have more suitable solutions. No doubt this is the main handicap.

This is necessary nevertheless, if safety consists of installing an obstacle to ensure that the outcome of an accident is not serious but slight, or to eliminate the elements of risk by prioritizing safe road design so that the road is not a factor of danger for all road users.

Who´s safer? Are we sheep?

Meanwhile, bikers feel threatened by roads designed for cars, who just through error, could end up in a deadly situation on these barriers.

Javier Rodríguez

* How does the UNE135900 (2004) work?

The intention was to establish standards for testing and evaluation of the results of the new SPM elements.

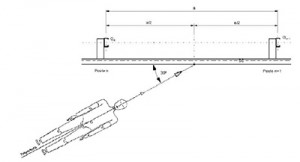

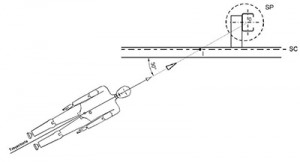

A Hybrid III dummy was modified to that effect and used protective rider equipment.

The test is carried out controlling the parameters of the test.

The dummy is launched at a speed of 60km/h and with an angle of 30 ° on several points of the safety barrier, according to the test carried out.

|

|

The result of the launch shows it caught by the sensors of the dummy, which is evaluated up to three times, the force and is measured in the neck and chest at the moment of the impact, as well as the injuries caused to the head.

These parameters were established by medical experts to determine the survival of the biker in case of a crash with one of the points of protection.

The result of the test, two levels of severity are established, being level I the safest in the case of impact.

If any of the parameters were level II, this one would immediately be the level of efficiency of the protection system, so that all the measurements have to be inside the range of level I or II.

If any of the parameters were level II, this one would immediately be the level of efficiency of the protection system, so that all the measurements have to be inside the range of level I or II.

If any parameter exceeds the values of level II, it is considered not to be a suitable system as it would result in certain death.

If one of the parts of the dummy exceeds the system it is considered not to be a suitable system.

If the SPM passes the safety tests of a biker´s crash, it also must be tested by launching the vehicle for which the safety barrier was approved in order to keep at least the same standards of effectiveness in this test. That is, if the barrier was designed and approved for light vehicles up to 1500kg, the crash tests of that vehicle against the barrier mounting the SPM should also meet the criteria.

Leave a Reply